Word to the Wise: The most common issues with drilling data

February 11, 2020

This article will briefly address the shortcomings of the most common means of drill problem research.

Each week, XI Technologies scans their unique combination of enhanced industry data to provide trends and insights that have value for professionals doing business in the WCSB. If you’d like to receive our Wednesday Word to the Wise in your inbox, subscribe here.

In today’s economy, drilling departments are working with a slim margin for error. Smaller drilling programs working with even small drilling budgets result in greater pressure to reduce well construction costs. More important still is the necessity to avoid problems and cost overruns.

There’s no better way to prevent future problems than by learning from the past. When drilling in a developed area, there’s information to be had for companies willing to do their due diligence. Companies who do their research can greatly reduce the risk of drill problems by knowing and planning for the potential hazards that lie ahead.

But sifting through that data isn’t easy, and the methods used to collect and research drilling data each come with their own challenges. Those that are aware of these potential issues and shortcomings are best prepared to overcome them.

Public data – There’s more you need to know

The first place to look for data to build your drill programs is with public data. However, there’s a lot of room for interpretation within AER Directive 059’s definitions around drill problem reporting guidelines. Since not all problems are being reported, you need to lean on additional sources. The issue is even more significant outside of Alberta, where there is no available database of drill problems.

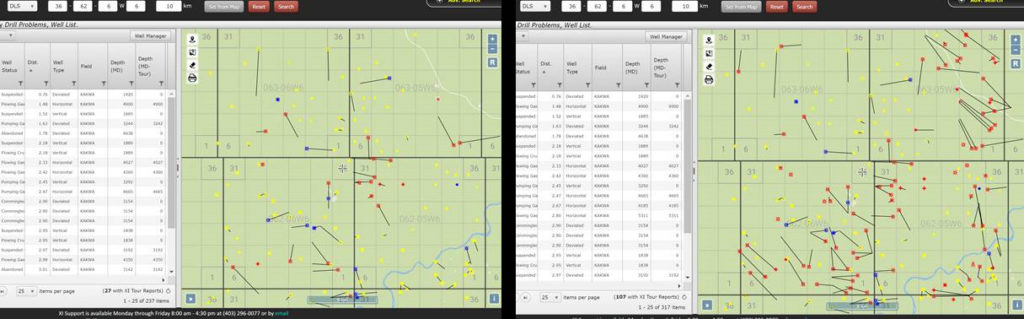

Above is an example of how much information can be lost when simply relying on public data. On the left are wells with reported circulation losses within 10km of 36-62-6W6 (237 wells, according to public records). On the right are an additional 74 wells identified by XI’s Drilling Database, as having experienced losses.

Your own experience

If you’ve been drilling an area for a few years, lessons will have been learned and known pitfalls can be avoided. The problem is that conditions are always changing, and new variables are thrown your way for every well you drill. In the Montney, for example, the geology can look completely different between two wells a mere 5 km apart.

You need to look over the fence and track the issues that others are having too. Just because something hasn’t happened to you yet, doesn’t mean it couldn’t!

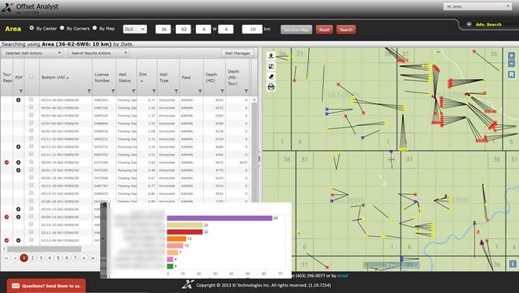

Above shows you 90 wells identified in XI’s Drilling Database with problems involving ‘Fishing’, and the operators who drilled them (names have been blurred). You could be operating in this area and not had that issue with any of your wells (yet), but with this information, you’d be prepared to deal with it knowing it’s an issue in the area.

Leaning on your service providers

This is the trend these days, with smaller internal drilling teams driving companies to rely on drilling service providers and their data and experience. They may have experience in your area; they may have data to support their work. But do they have the important data you need? If a problem occurred on a well that wasn’t theirs, aren’t you missing a piece of the puzzle? They could be subject to similar data gaps as you are in relying on internal information, with the difference being that you are ultimately the one responsible for the decisions made from this data.

Moreover, it’s only natural for a service company to share information that positions them in the strongest position for your business. Whether they’re trustworthy or not, their goal is to win your drilling business, not provide unbiased data.

Old school research: Finding the nearest 3-4 offsets and scanning the tour sheets

“It takes 4 hours a well to scan and read a set of our tour sheets! How much time do you think I’ve got?!?”

This is the reality our industry has struggled with, that we’ve heard from many clients over the years. Scanning through tour sheets manually just isn’t practical anymore, particularly not when drillers are tasked with doing more with less. The solution to this is digitized drill records, which both speeds the delivery of data but more importantly, expands the scope of research. The risks are too high to restrict research to just a few offsets. You need to see more data, more easily.

Looking for actual incidents…what about the situations that were successfully avoided?

It’s natural when trying to avoid drilling incidents to look for wells that had problems. But this is asking the wrong question. Instead of merely finding wells that had a problem, try looking for wells that indicate potential problems. It’s a slight shift in perspective that helps find important pieces of the puzzle. You want to learn not only from the mistakes of the past but also from the solutions of the past.

The Solution

So if these are the issues with the most common ways of getting drilling data, what’s the solution? Simply put, companies can’t rely on one method of collecting data for their research. They need to get as much data from different sources as possible while recognizing the potential issues of each.

Modern solutions can make that data easier to collect and to parse, helping close each of these gaps. To discover how XI can help you with data collection and analysis, book a personalized demo of our OffsetAnalyst software or download a paper on how a client found success in their drill planning by using it.